Solutions

Explanation:

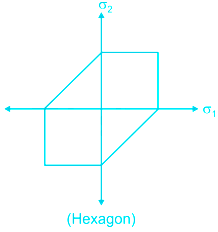

Maximum shear stress theory

(Guest & Tresca’s Theory)

According to this theory, failure of the specimen subjected to any combination of a load when the maximum shearing stress at any point reaches the failure value equal to that developed at the yielding in an axial tensile or compressive test of the same material.

Graphical Representation

For no failure

For design

σ1 and σ2 are maximum and minimum principal stress respectively.

Here, τmax = Maximum shear stress

σy = permissible stress

This theory is well justified for ductile materials.

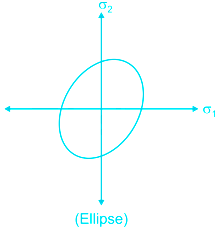

Maximum shear strain energy / Distortion energy theory / Mises – Henky theory.

It states that inelastic action at any point in body, under any combination of stress begging, when the strain energy of distortion per unit volume absorbed at the point is equal to the strain energy of distortion absorbed per unit volume at any point in a bar stressed to the elastic limit under the state of uniaxial stress as occurs in a simple tension/compression test.

for no failure

For design

It cannot be applied for material under hydrostatic pressure.

All theories will give the same results if loading is uniaxial.

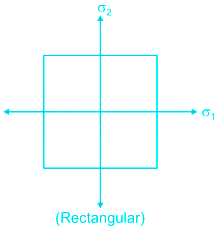

Maximum principal stress theory (Rankine’s theory)

According to this theory, the permanent set takes place under a state of complex stress, when the value of maximum principal stress is equal to that of yield point stress as found in a simple tensile test.

For the design criterion, the maximum principal stress (σ1) must not exceed the working stress ‘σy’ for the material.

for no failure

for design

Note: For no shear failure τ ≤ 0.57 σy

Graphical representation

For brittle material, which does not fail by yielding but fail by brittle fracture, this theory gives a satisfactory result.

The graph is always square even for different values of σ1 and σ2.

![]()

Maximum principal strain theory (ST. Venant’s theory)

According to this theory, a ductile material begins to yield when the maximum principal strain reaches the strain at which yielding occurs in simple tension.

For no failure in uniaxial loading.

For no failure in triaxial loading.

For design, Here, ϵ = Principal strain

σ1, σ2, and σ3 = Principal stresses

Graphical Representation

This theory overestimates the elastic strength of ductile material.

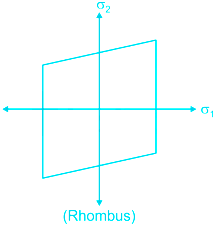

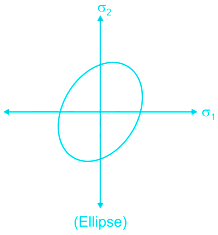

Maximum strain energy theory (Haigh’s theory)

According to this theory, a body complex stress fails when the total strain energy at the elastic limit in simple tension.

Graphical Representation.

for no failure

for design

This theory does not apply to brittle material for which elastic limit stress in tension and in compression are quite different.

Get latest Exam Updates

Get latest Exam Updates

×

×